MAAD ZGM-3000/1.25 BENDING MACHINE SHEET METAL BENDING MACHINE MECHANICAL ELECTRIC MAAD ZGM-3000/1.25

- MAAD ZGM-3000/1.25 BENDING MACHINE SHEET METAL BENDING MACHINE MECHANICAL ELECTRIC MAAD ZGM-3000/1.25

Technical parameters:

- working width - 3100 mm

- max. thickness of the bent sheet - 1.25 mm ( for Rm<400 MPa )

- width of the bending beam - 20 mm

- maximum bending angle - 135 degrees

- clearance between beams - 80 mm

- weight of the machine - 2050 kg

- electrical system 400 V

- motors on the bending beam - 2 x 2.2 kW

- motor on pressure bar 0,55 kW

- setting the bending angle in the range of 0 - 135 degrees

Machine dimensions:

- height - 1,320 mm

- width - 4,550 mm

- depth - 1,150 mm

The main working elements of the bending machine are the beams: fixed, pressure and bending beams.

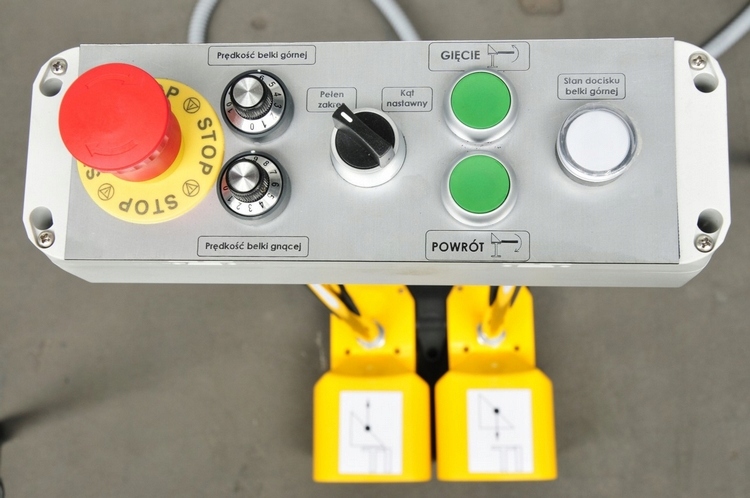

The pressure beam is a movable beam used to fix the sheet in the desired position. It is equipped with a replaceable working segment attached to the beam body with screws. It also has adjustable clamping force/height. It is raised and lowered by foot pedals and the speed of the beam is set steplessly by a potentiometer on the control panel.

The bending beam, like the pressure beam, is equipped with an interchangeable working segment attached to the beam body with screws. The rotary movement of the bending beam is carried out by means of buttons from the control panel, and its speed is infinitely adjustable by means of an independent potentiometer located on the control panel. In AUTO mode, actuating the bending beam with a button from the desktop, causes it to move in a full bending cycle to the initial position.

Locking knob allows stepless adjustment of the bending angle of the bent sheet from 0 to 135 degrees. The selection of the range of movement of the bending beam (movement up to the set bending angle or movement over the entire range of bending beam operation) is made using a switch located on the control panel of the bending machine.

Electric-mechanical drive controlled by pedals allows the operator to use both hands - the movement of the pressure bar with foot pedals allows the operator to accurately position the sheet metal in the working space of the bending machine with both hands.

The machine is equipped as standard with bumpers with millimeter graduations for setting the position of the workpiece also acting as a table.

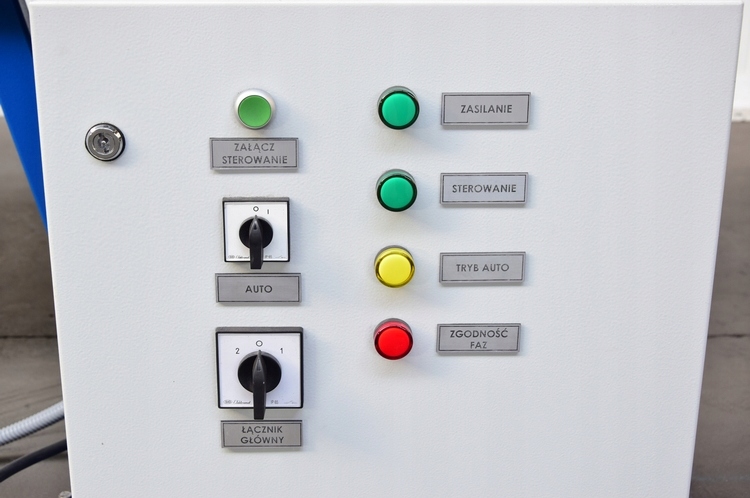

The electrical system of the bending machine adapted for power supply from a three-phase AC network 400 V / 50 Hz in a 5-wire TN-S or TN-C-S system.

For the safety of the operator, all controls of the working beams and mounted in the bending machine desktop are powered by 24 V.

Bending machine components are made on precision CNC machine tools.

The bending machine is covered with a double layer of high-quality paint - the painting process is performed in a professional, heated and ventilated paint shop.

The machine is equipped as standard with bumpers with millimeter graduations for setting the position of the workpiece also acting as a table.

The electrical system of the bending machine adapted for power supply from a three-phase AC network 400 V / 50 Hz in a 5-wire TN-S or TN-C-S system.

For the safety of the operator, all controls of the working beams and mounted in the bending machine desktop are powered by 24 V.

Bending machine components are made on precision CNC machine tools.

The bending machine is covered with a double layer of high-quality paint - the painting process is performed in a professional, heated and ventilated paint shop.

WARUNKI GWARANCJI I SERWISU

-

Towary zakupione w naszym sklepie są nowe i oryginalne oraz objęte są pełną gwarancją producenta lub importera.

- W przypadku reklamacji, należy zgłosić usterkę do Sprzedawcy lub Autoryzowanego Punktu Serwisowego producenta danego urządzenia. Jeśli uszkodzony produkt objęty jest gwarancją typu „door to door” należy postępować zgodnie z procedurą podaną w karcie gwarancyjnej.

- Okres gwarancji wynosi 12 miesięcy dla firm lub 24 miesiące dla osób prywatnych.