- MAAD ZB-1.5 E gouging machine is used for gouging, curving, folding and bending all kinds of metal sheets up to 1.5 mm thick. Gouging machine ZB-1.5 is a device used for processing steel sheets up to 1.5 mm,copper,aluminum etc.

MAAD ZB-1.5 E FOLKING ROLLER - Electric version

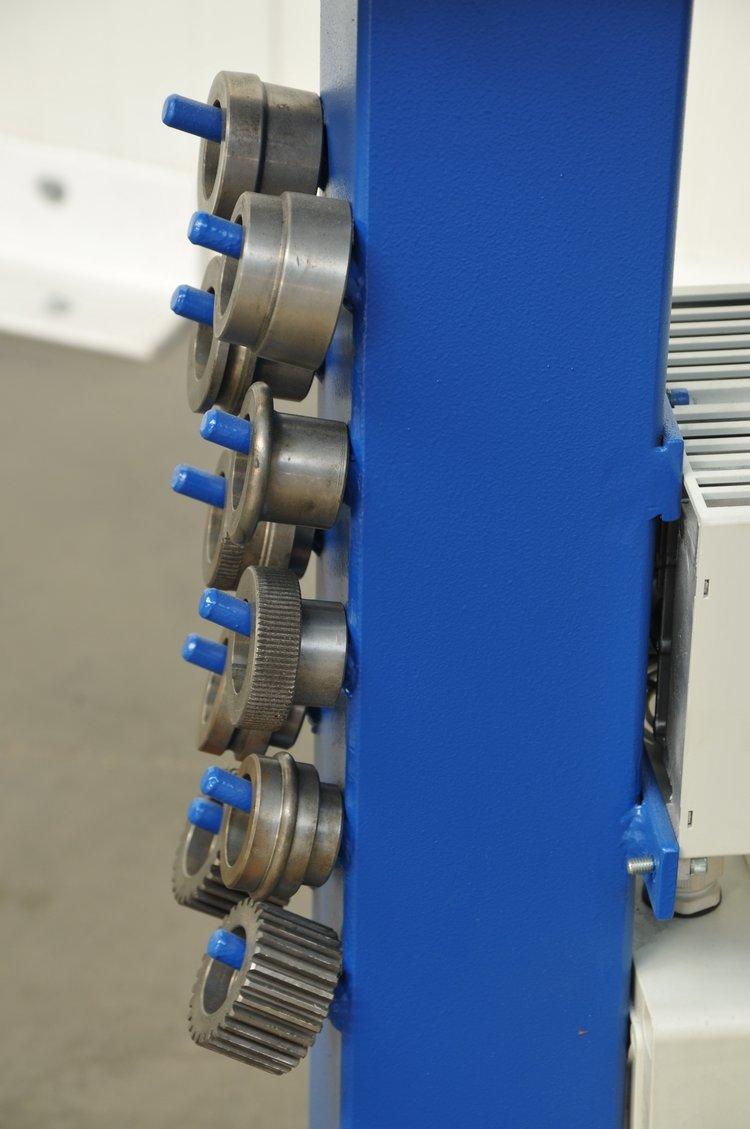

MAAD ZB-1.5 gouging machine is a device used for processing steel sheets up to 1.5 mm thick, copper, aluminum, etc. Ideal for bending the edges of sheet metal, crimping them or spinning them out. The broad spectrum of performance ensures application in a wide range of industries from sheet metal work for renovation, to finishing gutter system components, and all kinds of ventilation fittings.MAAD ZB-1.5 gouging machine is used for gouging, curving, folding and bending all kinds of metal sheets up to 1.5 mm thick. The working elements of the gouging machine are sets of rollers mounted on rollers. Each set of rollers makes a different profile out of sheet metal. Rollers are mounted on two rollers. Adjusting the distance between the two rollers and the longitudinal displacement of the top roller relative to the bottom roller affects the shape of the profile of the gouged plate.

Technical parameters/equipment:

- working depth - 150 mm

- max. thickness of processed sheet - 1.5 mm ( for Rm<400MPa )

- diameter of working rollers - 2 x 35 mm

- Motor power - 1.1 kW

- Gearmotor transmission - 1:30

- Power supply of the machine - single-phase

- Speed of the rollers - 0 - 60 rpm

- Traverse speed of the processed sheet - 0 - 9.6 m/min

- left and right speed controlled from separate foot switches

- infinitely variable speed control of the working shafts via a potentiometer

- 6 sets of work rollers included

- sheet guide included

Gabarities:

- height - 1300 mm

- width - 300 mm

- length - 700 mm

- weight - 100 kg

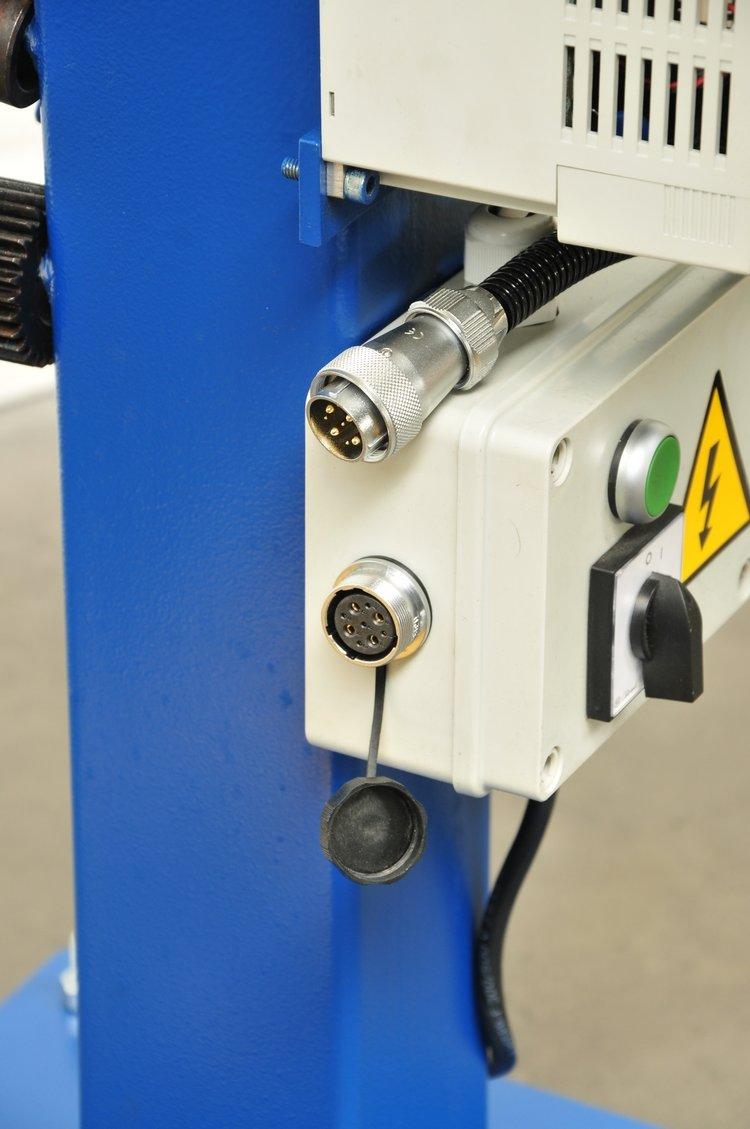

The electric-powered version of the grooving machine is characterized by the following features:

- left and right turns - the use of two separate control pedals,

- adjustable speed range from 0 to 60 revolutions / minute - the use of an inverter,

- worm gearmotor connected to the working shafts by a prone coupling,

- machine stand included.

The work rollers are made on a CNC lathe which ensures high dimensional accuracy.

Gouging machines of our production have been successfully used for many years both in small sheet metal workshops and in serial production, for example, in companies in the ventilation industry.

The grooving machine is covered with a double layer of high-quality paint - the painting process is performed in a professional, heated and ventilated paint shop.

WARUNKI GWARANCJI I SERWISU

-

Towary zakupione w naszym sklepie są nowe i oryginalne oraz objęte są pełną gwarancją producenta lub importera.

- W przypadku reklamacji, należy zgłosić usterkę do Sprzedawcy lub Autoryzowanego Punktu Serwisowego producenta danego urządzenia. Jeśli uszkodzony produkt objęty jest gwarancją typu „door to door” należy postępować zgodnie z procedurą podaną w karcie gwarancyjnej.

- Okres gwarancji wynosi 12 miesięcy dla firm lub 24 miesiące dla osób prywatnych.